The Rack Manufacturers Institute (RMI) recently revised its American National Standards Institute (ANSI) standard for cantilever storage racks. The updated ANSI MH16.3-2025: Design, Testing, and Utilization of Industrial Steel Cantilever Storage Racks is now available for purchase.

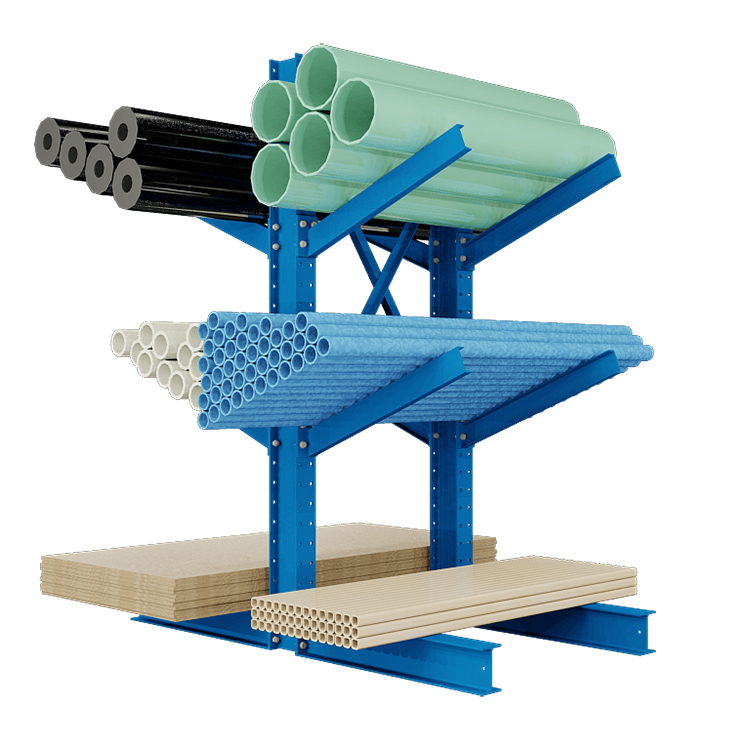

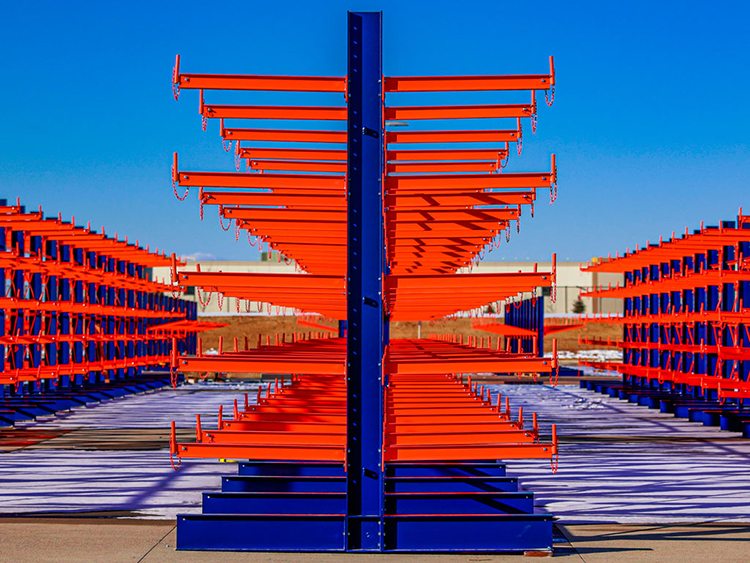

Cantilever racks store long, bulky, or irregular loads—such as lumber, tubing, pipe, or sheet goods—on arms extending from upright columns. MH16.3 provides engineers, manufacturers, and end users with the technical framework needed to design and evaluate these systems for safety and structural reliability.

The first edition of MH16.3 appeared in 2016. The 2025 edition reflects almost a decade of new research, engineering practice, and field experience, noted Andrew Bishop, Principal Engineer at UNARCO Material Handling. The company is a member of RMI, and Bishop—Chair of RMI’s Standards Advisory Committee—played a key role in revising MH16.3-2025.

“The primary goal is always to make sure the racking structures are safe. As we learn more every year, we work those insights into the standard,” he noted. “Additionally, the committee reorganized several existing sections to make the content easier for engineers, manufacturers, and end users to navigate.”

MH16.3 Revisions Include Updates to Inspection, Loading, and Seismic Guidance

The updated MH16.3 clarifies expectations around installation and post-installation inspection, noted Bishop. The revision reinforces that the engineer of record must verify the design intent and identify the elements requiring inspection.

The updated MH16.3 clarifies expectations around installation and post-installation inspection, noted Bishop. The revision reinforces that the engineer of record must verify the design intent and identify the elements requiring inspection.

“These inspections were always expected, but the standard now states it more clearly,” he said. “It’s important for rack owners to be sure the engineer notes what inspections are required prior to commissioning.”

Further, these clarifications support more consistent installation practices, he added. “It also helps facilities verify that the rack configuration matches the engineered design.”

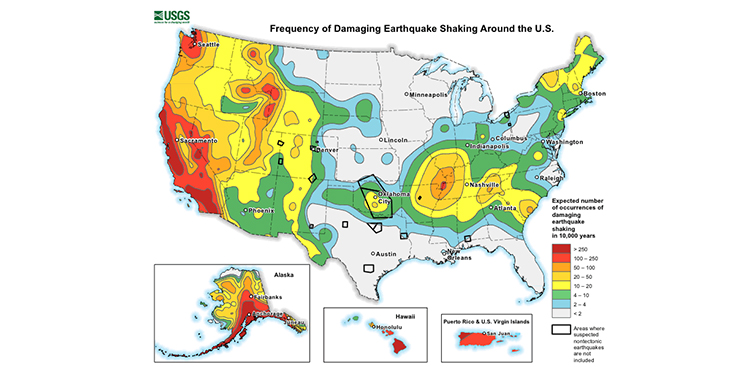

Additionally, MH16.3-2025 updates several loading requirements, including how pallet load, seismic load, and snow load calculations are combined. These changes match the latest reference standards used by structural engineers in other construction industries, said Bishop. “This keeps cantilever rack design aligned with current structural engineering methodology.”

Several updates strengthen the standard’s seismic provisions. MH16.3 now references a free online tool for obtaining site-specific earthquake data. The revised text also updates overturning load percentages for anchorage design to eliminate confusion between two similar numbers that previously appeared in different sections. These changes support more consistent design practices for seismic regions, noted Bishop.

New Product Load Section Helps Prevent Arm Overload

One of the most impactful additions is a new product load section—supplemented by figures in the commentary—that illustrates how load placement affects arm forces. This addition directly supports safer operation.

“If a forklift driver loads a long item off-center, one arm can be overloaded,” Bishop explained. “Illustrations in the commentary section of the standard show how that happens.”

“If a forklift driver loads a long item off-center, one arm can be overloaded,” Bishop explained. “Illustrations in the commentary section of the standard show how that happens.”

The new content provides:

- Visual examples of centered versus off-center loading.

- The resulting arm force differences.

- Equations engineers can use to design for reasonable loading tolerances.

Bishop emphasized the importance of this revision for end users. “It helps both the engineer and the operator. It can be difficult to perfectly center a 12-foot load, which is what cantilever rack often holds. An off-center load can overload an end arm, so engineers need to design them with an offset tolerance. But also, if an operator sees the load hanging too far off to one side, the standard explains why it needs to be recentered.”

Additionally, the earlier version of MH16.3 only required that arms not deflect below horizontal under load. The 2025 revision introduces an explicit deflection limit, similar to criteria already used for pallet rack beams as detailed in ANSI MH16.1: Design, Testing, and Utilization of Industrial Storage Racks.

“We added a deflection limit because there wasn’t a strict requirement previously,” Bishop said. “These limits help prevent excessive arm bending and promote more uniform design practices.”

MH16.3 Strengthens Seismic and Stability Analysis

The updated ANSI MH16.3-2025 standard introduces a more precise approach to assessing cantilever rack performance under seismic and stability loads through the use of the direct analysis method (DAM).

The direct analysis method provides a more accurate representation of how cantilever columns and arms behave under load, but the differences between the design methods are less significant at lower second-order (B2) effect values. The standard permits a cross-aisle effective length factor of K = 1.0 when using DAM for stability calculations. The effective length method still applies if the force amplification factor B2 is less than or equal to 1.5.

“Cantilever racking now uses the same stability design method applied to selective rack,” Bishop explained. “DAM helps engineers capture nonlinear behavior, second-order effects, and load redistribution mechanisms. The intent is to give engineers a more accurate picture of how the rack performs during a seismic event.”

To support this, MH16.3 advises engineers to include second-order effects—structural deformations that occur as loads shift and members deflect—when performing seismic and stability calculations.

The standard further requires the use of notional loads when using the DAM, small horizontal forces applied at each load level to account for geometric imperfections introduced during fabrication and installation. Together, these requirements produce a far more accurate assessment of how cantilever rack structures behave during earthquakes, noted Bishop.

“When applying DAM with second-order effects, the engineer uses the real load and applies notional forces, so the design captures those initial imperfections,” he said.

To address inconsistencies in field practice, the revised standard clarifies cross-aisle and down-aisle bending requirements in the unbraced area between the slab and the first brace panel. This area is particularly important during seismic events, added Bishop.

“MH16.3 also updates column-to-base design procedures and baseplate/anchor requirements to align with the new DAM provisions,” he noted. “These changes ensure that anchorage design keeps pace with contemporary engineering practice.”

Access the Updated Standard, Rack Safety Resources

The newly revised ANSI MH16.3-2025 standard is available for purchase. RMI also provides additional resources to support safer rack system design and use. These include presentations, a glossary, case studies, and FAQs. Visit mhi.org/rmi for more information.