Today’s warehouses are taller, heavier, and more automated than ever. But while rack heights and loads continue to grow, concrete slabs-on-grade have not kept pace. Often, warehouse floor design does not account for the concentrated loads exerted by modern storage rack systems. These warehouse floor loading gaps often result in a concrete slab of insufficient thickness to handle the weight of the loaded storage racking.

To address this growing disconnect, the Rack Manufacturers Institute (RMI) recently submitted a proposed technical change to the American Society of Civil Engineers’ ASCE/SEI 7-22 standard. Specifically, RMI’s Standards Advisory Committee proposed technical changes to Section 4.4 and Table 4.3-1 regarding warehouse floor loading requirements. The proposal introduces guidance for concentrated slab loads in warehouses and similar buildings equipped with storage racks. It also recommends a straightforward formula for calculating minimum floor loading assumptions.

“More and more, facilities are installing racking systems that the slab just can’t handle,” said Andrew Bishop, Research & Development Engineer at UNARCO Material Handling. The company is a member of RMI, and Bishop—Chair of RMI’s Standards Advisory Committee—played a key role in drafting the proposal.

“Our goal for the revision is simple,” he continued. “We want to give building designers the tools to plan ahead, instead of running into expensive fixes later.”

Why It Matters: Uniform Live Loads Don’t Match Reality

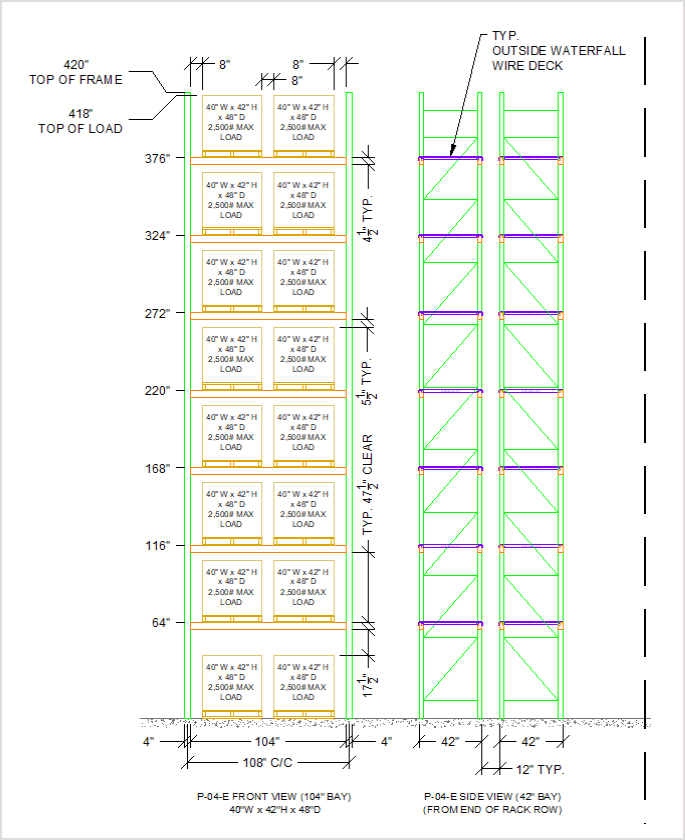

The current ASCE/SEI 7 standard calls for calculating warehouse floor loading based on a uniform live load of 125 pounds per square foot (psf) for light-duty storage occupancy or 250 psf for heavy-duty storage occupancy. But unlike uniformly distributed loads, rack uprights concentrate heavy loads onto small areas of the slab. That often represents thousands of pounds per post.

The current ASCE/SEI 7 standard calls for calculating warehouse floor loading based on a uniform live load of 125 pounds per square foot (psf) for light-duty storage occupancy or 250 psf for heavy-duty storage occupancy. But unlike uniformly distributed loads, rack uprights concentrate heavy loads onto small areas of the slab. That often represents thousands of pounds per post.

“In practice, the uniform load requirement works fine for bulk floor storage,” Bishop explained. “But when it comes to racks, especially tall ones, the reality is very different.”

As a result, slabs in many newly constructed warehouses—especially spec buildings built without a tenant in mind—may not be able to handle the concentrated post loads of the racks they eventually house.

RMI’s Solution: A Clear, Practical Formula for Calculating Warehouse Floor Loading

The RMI proposal gives engineers and developers a clear baseline to design against in the absence of tenant-specific rack loading information, noted Bishop.

Key assumptions include:

- One storage position at every 5 feet of building height.

- 5,000 pounds of load per storage position.

- Load concentration based on a standard grid pattern frequently seen in real-world installations.

This model results in a scalable calculation tied to the building’s clear height. This serves as a proxy for the racking systems most likely destined for the space.

“The proposed formula isn’t a catch-all,” he said. “But it covers the majority of use cases and gives building professionals a defensible approach when the future layout is unknown.”

From Standards to Construction: Aligning Codes with Reality

Historically, building designers don’t consider slabs-on-ground to be structural elements during building design. However, that view is shifting, particularly with recent updates to the American Concrete Institute’s ACI 360. This standard provides guidance for designing slabs-on-ground that support racking.

RMI’s proposal also aligns with upcoming language in ACI 360 Chapter 12, which addresses slab-on-ground performance under concentrated loads.

“We’re not trying to tell concrete engineers how to do their jobs,” continued Bishop. “We’re just pointing out that this is a recurring problem. Building designers and owners would benefit from warehouse floor loading guidance at the outset of the design process. Instead, they often discover the floor slab’s insufficient load capacity during rack installation.”

Long Path to Code Adoption—but Actionable Now

The proposal is under consideration for inclusion in ASCE 7-28, which would potentially be adopted into the 2030 International Building Code (IBC). That means it may be several years before these changes formally shape local code requirements.

“However, there’s an urgent need for awareness of this issue now,” Bishop emphasized. “This is especially true for developers designing spec buildings. It’s also critical information for architects and engineers specifying slab requirements without known rack loads.”

In the interim, RMI recommends:

- Engaging a qualified slab engineer early in the design process.

- Requesting rack load data from storage system manufacturers.

- Considering flexible design approaches—like pouring the slab after tenant selection—to allow for customization.

- Avoiding retrofit headaches by designing for realistic concentrated loads from the start.

A Shared Goal: Safer, More Functional Facilities

While warehouse floor loading may seem like a niche issue, it can have far-reaching consequences. Among them are equipment performance and safety, facility uptime, and repair costs.

“Ultimately, this proposed revision isn’t about racks. It’s about readiness,” Bishop concluded. “If a warehouse is going to support racking, that information needs to be part of the slab design from day one.”

Learn More About Potential Warehouse Floor Loading Issues

In the Frequently Asked Questions (FAQs) section of its website, RMI offers insight into potential warehouse floor loading issues. Additionally, RMI members are available for guidance and recommendations about floor and concrete slab design. For more information, visit mhi.org/rmi.