At ProMat 2025, the Rack Manufacturers Institute (RMI) presented an on-floor education session titled “Storage Rack Safety 101.” The seminar focused on the essentials of rack safety, including ways to maintain compliant and operational warehouse racking systems.

Mark Rousseau, Vice President of National Accounts and Strategic Partnerships at RMI member Damotech, and Brian Boals, National Sales Manager for National Accounts at RMI member Ridg-U-Rack, led the presentation. During the 45-minute session — now available as a recording — the discussion covered a range of rack safety topics. These included damage prevention, rack inspections, and regulatory implications. The pair underscored RMI’s key message: rack safety is not optional.

Rack Safety in a Dynamic Environment

Rousseau opened the session by emphasizing that once a rack installation is complete, it becomes part of a live environment. That is, constantly exposed to movement, impact, and operational wear.

“After commissioning a rack system, it’s exposed to forklifts moving in and out of the aisles and pickers walking through it,” he said. “That means it must be maintained properly to ensure rack safety.”

The risks are both frequent and serious. Rousseau outlined some of the most common issues encountered in the field, including:

- Aisle-facing column damage from forklifts that weakens the system.

- Bracing failures that decrease the system’s stability.

- Anchors sheared off by outriggers that increase the risk of collapse.

- Disengaged connectors that can cause beams to separate from uprights.

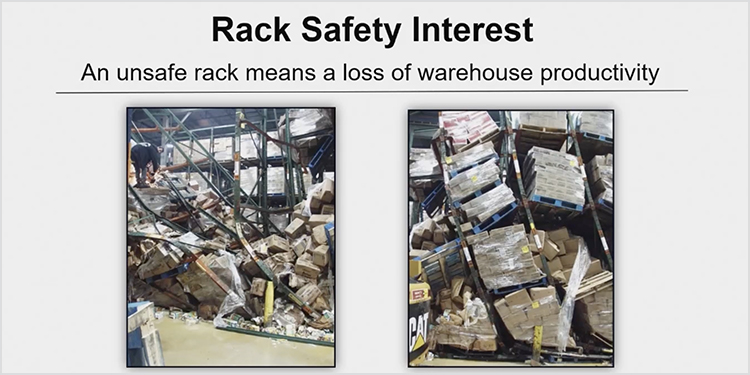

“Damage happens all the time,” he warned. “The last thing anyone wants to see is a collapse that results from the damage. Not only because it affects productivity, but also because it could cost someone their life.”

Cheap Fixes Can Be Dangerous Mistakes

Improvised repairs — like field welding or chaining racks together — commonly occur. Rousseau cautioned against them.

“Even operations that have a certified welder, welding to repair rack is difficult in the best circumstances,” he said. “From prepping the area adequately to having the weld take shape properly — then having an engineer sign off. In-house welding is challenging and not something RMI recommends.”

Rousseau pointed to simple safety accessories that can reduce or prevent many impact issues. These include upright protectors, end-of-aisle barriers, bolt-in shelf supports, and properly rated decking. “A connection pin might only cost $1.50,” Rousseau noted. “But it could save someone’s life if a forklift disconnects a beam.”

Inspections Are Key to Rack Safety

Boals took over for the second half of the session. He focused on inspection strategies and long-term safety planning.

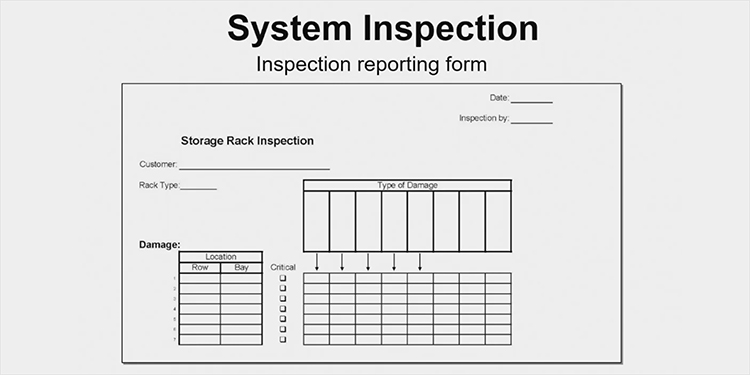

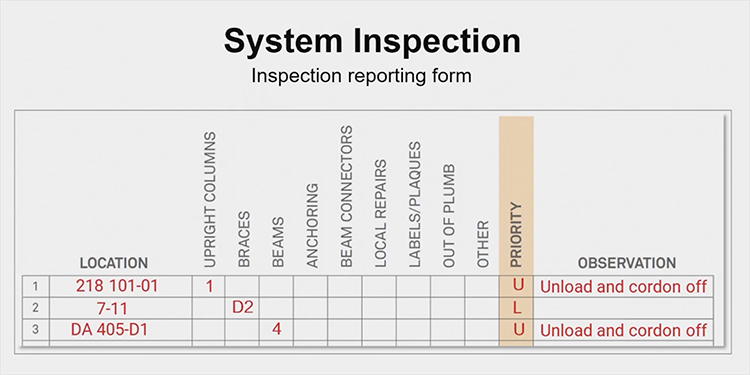

“Rack inspections are the first step to securing safer warehouse operations,” he said. “They are an integral part of documenting the health of your warehouse on a given day. But remember, an inspection only records the rack’s status on one day. It’s just a snapshot, because things change routinely.”

Boals outlined the importance of inspecting everything from damaged columns and beams to skewed shims and detached anchors. He advised paying particular attention to high-traffic areas like docks and freezers, where damage is more frequent.

“Once you have a column that’s compromised,” Boals explained, “the energy from the next impact travels to the path of least resistance. That’s how small damage turns into catastrophic failure.”

He also stressed the importance of load capacity plaques at the end of aisles to help operators understand safe loading limits.

“When the rack is installed, capacity plaques should be too,” advised Boals. “Also, anytime there’s a change in elevation or inventory stock keeping units (SKUs), those plaques should be updated.”

Inspection Frequency Depends on Risk

How often should inspections occur? Boals said it depends on the operation.

“If you have high operator turnover or tight aisles, monthly inspections might be warranted,” he explained. “At the very least, inspections should happen annually. But more frequent checks can reduce your insurance rates and protect your workers.”

Documentation is key — not just for internal tracking but for regulatory protection. “An inspection report is great,” Boals emphasized, “but it’s useless if nobody takes action.”

OSHA Is Watching

Toward the end of the session, Rousseau shared a sobering statistic: “In the summer of 2023, the Occupational Safety & Health Administration (OSHA) launched a national emphasis program (NEP) focused on warehousing. They found that injury rates in distribution centers were twice as high as in similar industries.”

He continued, “OSHA inspectors now have the legal authority to evaluate a facility’s racking. This includes not just damage, but also for inspection programs and signage compliance. If you haven’t concluded that rack safety is important, OSHA already has.”

Boals echoed the concern, warning that what starts as a single issue can trigger broader scrutiny. “One of the best defenses from an operational standpoint is to have a rack inspection program as part of your daily operation,” he said. “If you can show the OSHA inspectors that you’re documenting incidents and responding to them promptly, chances are they will be a little easier to deal with.”

Final Takeaways

In summarizing the session, Boals noted: “A damaged rack doesn’t get better by itself. If you don’t take care of it, damage issues only grow.”

He and Rousseau left participants with five key actions for warehouse operators to ensure rack safety:

- Inspect regularly based on operational risk.

- Install and maintain proper safety accessories.

- Update load capacity plaques with SKU changes.

- Avoid in-house fixes without engineering approval.

- Document inspections and take corrective action promptly.

Above all, treat rack safety as part of an operation’s core safety culture, not just a compliance checkbox. As Rousseau concluded, “You want your employees to operate in a safe environment and go home to their families.”

To watch the recording of the education session, click here. For more information about how to improve rack safety, RMI offers a free list of Frequently Asked Questions on its website, mhi.org/rmi.