Jammed Pallet Flow System? Follow These Best Practices To Safely ...

Pallet hang-ups can happen in even the best maintained, properly loaded pallet flow rack system (also known as “gravity flow”). Jams can be caused by a variety of reasons, including a pallet that’s settled onto the tracks, debris in the ...

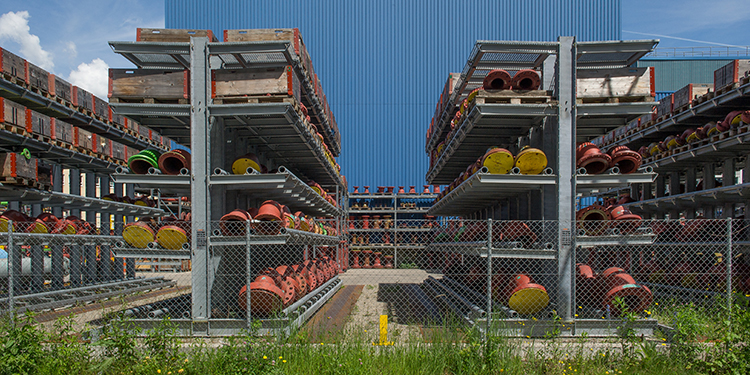

Understanding End Caps: Why They Might Be Used On Cantilevered ...

Whether they’re constructed from roll-formed steel or structural steel, cantilevered storage rack incorporates central, vertical columns from which horizontal arms project perpendicularly on one or both sides. Because the ends of the arms and bases are exposed, an optional steel ...

How Pallets Contribute To The Safe Use Of Pushback Rack ...

As with the vast majority of industrial steel storage rack systems, last-in/first-out (LIFO) pushback racking systems are designed for use with specific pallet types, loads and rack configurations. Operators, therefore, should be trained to only load a pushback system with ...

Why Cantilevered Storage Rack Arms Are Designed To Match Load ...

Cantilevered storage rack features horizontal arms that project perpendicularly from vertical columns on one or both sides. Because they have no vertical columns connecting the arms on the aisle face, they are ideal for holding long loads, such as bar ...

How Height-To-Depth Ratio Contributes To Overall Storage Rack Stability

A key objective of safe rack design is to ensure the finished structure won’t topple over when subjected to horizontal forces such as an earthquake, forklift impact, or high wind. To significantly minimize this risk, Section 8.1 of RMI’s ANSI ...

The “Dos and Don’ts” Of Pallet Flow Rack

Whether you own a pallet flow rack system (also referred to as “gravity flow” rack), or are considering investing in one, ownership comes with a variety of responsibilities. These include ensuring that the structure complies with applicable standards and is ...

The Importance Of Uniform Load Placement To Cantilevered Storage Rack ...

Designed and engineered to store very long loads — such as building materials including piping, lumber, or bar stock — cantilevered storage rack structures incorporate central, vertical columns from which horizontal arms project perpendicularly on one or both sides, with ...

Minimize The Risk Of Load Beam Disengagement With Locking Devices

To reduce the chance of a load beam becoming disengaged from the storage rack structure, rack manufacturers typically include locking clips, pins and/or bolts. They secure the connection of the beams to the upright columns at every point of contact ...

Don’t Miss RMI’s Two ProMatDX 2021 Education Seminars On Rack ...

At ProMatDX 2021, members of the Rack Manufacturers Institute (RMI) will present two separate education sessions covering the safe design and use of industrial steel storage rack. Open to all ProMatDX attendees free of charge, the two sessions will include ...