How Point Loads And Uniformly Distributed Loads Affect Safe Rack ...

When placed in industrial steel storage racks, a uniformly distributed load is one whose weight is evenly spread over the entire surface of the rack’s beams or deck. Conversely, a point load is one with its weight significantly concentrated in ...

Building Codes And Their Importance To Rack Design

In spite of being a standalone structure, the safety of an industrial steel storage rack’s design and installation is nearly always vetted by one or more local jurisdictions — including state, county, or local municipality. The reason? The International Code ...

Use Rack Load Capacity Plaques And LARC Drawings For A ...

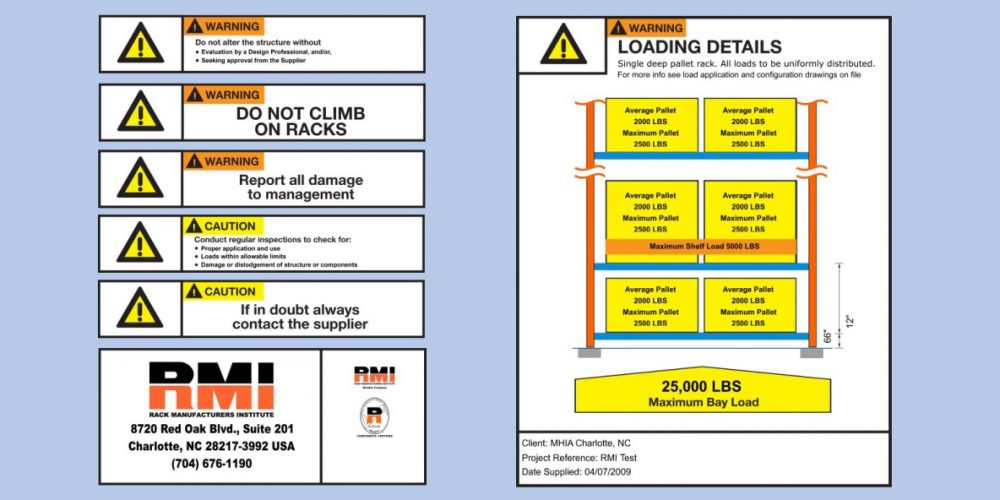

To ensure a safer, and, therefore, more productive operation, owners of industrial steel storage racking are responsible for posting rack load capacity plaques in conspicuous locations, and should refer to the system manufacturer’s load application and rack configuration (LARC) drawings ...

Not All Steel Is Created Equal: Why R-Mark Certification Matters

Steel is steel is steel—right? Wrong. And making that assumption when evaluating potential rack suppliers could lead to a system failure if the manufacturer uses a steel formulation that is not compatible with its production equipment. Reputable industrial steel storage ...

RMI Presents Two Education Seminars On Rack Design And Safety ...

At MODEX 2020, members of the Rack Manufacturers Institute (RMI) will present two separate on-show-floor educational sessions covering the safe design and use of industrial steel storage rack. Open to all MODEX attendees free of charge, the two sessions will ...

Why Pallet Quality Is Key To Safe Rack Utilization

Although industrial storage rack systems are specifically designed and engineered to support a given type of pallet and load, simply placing the approved pallet into a storage position isn’t enough to ensure the safety of the structure and facility personnel. ...

The Importance Of Matching Pallets To Rack Type For Safe ...

Products arrive in warehouses and distribution centers on any number of pallet types these days: two-way entry, four-way entry, skids, slip-sheets, nine-block, and more. Some pallets are designed with multiple boards—or stringers—spanning the bottom surface; others have a foot in ...

Rack Inspections: An Overview

Among the many best practices to ensure the safety of industrial steel storage rack systems and the workers around it, inspections are among the most critical. Indeed, there are several kinds of rack inspections, including: Inspections Required By Building Codes: ...

The Basics Of Storage Rack Safety Detailed In RMI’s ProMat ...

At ProMat 2019, held this past April in Chicago, members of RMI presented a free, on-floor seminar to attendees. Entitled “Storage Rack Safety 101,” the 35-minute session’s slides and audio were recorded for those who were unable to attend, or ...

Learn How To Design The Optimal Rack System For Traditional ...

With traditional retail distribution relying on full pallet movement and/or picked cases, while e-commerce distribution is typically comprised of reserve, full pallet storage used to replenish a pick module or other each picking system, it stands to reason that each ...