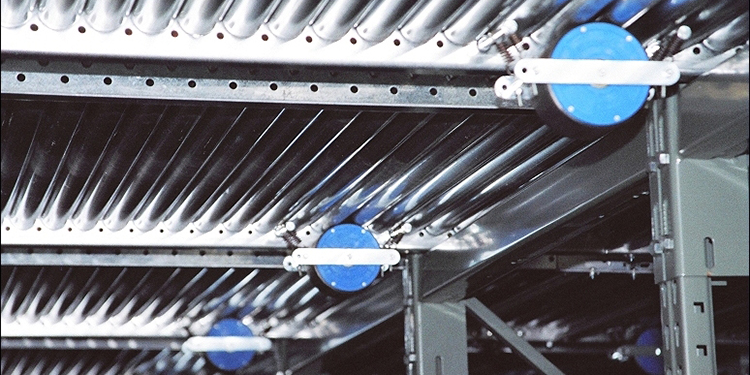

Applying Pallet Separators, Speed Controllers To Flow Rack

Because high-density pallet flow (also called “gravity flow”) rack is engineered to hold multiple pallet loads in a lane with a downward pitch, they are increasingly popular for use in case-picking operations. Full pallets are loaded from the back, or ...

Best Practices In Safe Operation Of Pallet Flow Rack

Pallet flow rack (also sometimes called “gravity flow”) is a high-density, dynamic storage system engineered to hold up to 20 pallets in a single lane. Loaded back to front for first-in/first-out load access, the pallets ride atop gravity wheel or ...

Rack System Enhancements That Further Mitigate Forklift Impacts

A previous blog entry reviewed a selection of optional guarding accessories. These add-ons are applied at the time of installation—or as a later retrofit—to aisle-side or end-facing rack columns (or to the floor in front of them) to minimize the ...

Point Versus Uniformly Distributed Loads: Understand The Difference

When placing loads of equal weight in storage racks, it’s important to remember that all pallets or loads are not created equal. Some pallets are designed with multiple boards—or stringers—spanning the bottom surface; others have a foot in each corner. ...

What’s Height-To-Depth Ratio, And Why Is It Important?

To significantly minimize the risk of a single row of standard steel storage rack from becoming unstable and overturning due to a seismic event, wind or forklift impact, Section 8.1 of RMI’s ANSI MH16.1-2012: Specification for the Design, Testing and ...

Don’t Forget To Check Permitting Requirements For Your Proposed Rack ...

Whether planning for a new rack system in a new location, or a new rack system in an existing location, the system cannot be installed until all applicable building codes have been satisfied. Further, a building permit must be issued ...

Making A Tight Beam-To-Column Connection

To ensure that a pallet rack beam does not separate from an upright rack column as a result of either an impact or seismic event, RMI’s ANSI MH16.1-2012: Specification for the Design, Testing and Utilization of Industrial Steel Storage Racks ...

Pallet Beam Deflection: How Much Is Acceptable?

When the specifications for a pallet support beam are determined by a qualified rack design engineer, the maximum amount of deflection—or bowing—permissible is included in the calculations as noted in Section 5.3 of RMI’s ANSI MH16.1-2012: Specification for the Design, ...

Why Are There Two R-Mark Certifications, One For Rack And ...

Offered as two separate certifications to manufacturers of industrial steel storage racks and of welded wire rack decking, RMI’s R-Mark assures storage rack users that the rack frame, beam and decking capacities shown in a unique design’s load table were ...