Rack Codes & StandardsRack Design & InstallationRack Inspection & MaintenanceRack Repair & ReconfigurationUncategorized

A Look at ANSI MH32.1

In order to safeguard your employees on elevated work surfaces, you’ll need to follow these standards. In the warehouse, much of your employee’s work will take place in overhead work areas that are designed to maximize the vertical space you ...

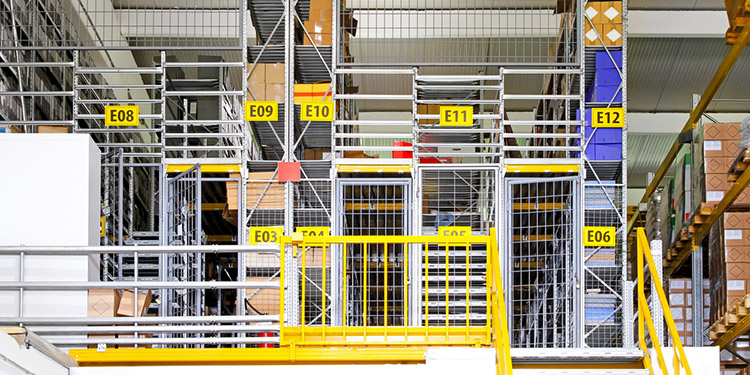

Retrofitting Racks for Individualized Picking

The nature of picking is changing and your operations may need to change with it. With the explosion of ecommerce over the past few years, warehouses that were not set up for picking eaches must find configurations that allow picking ...

Planning Your Rack System

With the right combination of equipment, you can meet your varied customers’ needs. The complexity of warehousing operations has been on a steady increase for the past decade or so. Now add in the pandemic and explosive demand for ecommerce, ...

Nine Benefits Of Rack Repair Kits

Pallet rack damage happens, often due to an impact from a forklift as it transports a load through the facility. Upon identification of a damaged rack section the structure should be isolated, and a qualified, professional rack engineer should be ...

How Rotationally Rigid Connections Enhance Rack Stability In Seismic Events

Depending on where a warehouse or distribution center (DC) is located within the United States, the design and engineering of its industrial steel storage rack structures may be subject to seismic requirements. As outlined in RMI’s ANSI MH16.1: Specification for ...

Is It Okay To Cut Pallet Rack Uprights?

Sometimes a rack owner will decide to relocate an existing pallet rack structure to a different location within the same facility — only to discover that the new space has a lower ceiling height than the original site. If only ...

Use These Specifications To Ensure The Safest Stairway Design For ...

To access overhead work areas for picking—such as rack supported platforms, elevated work platforms, and pick modules—workers must climb one or more flights of stairs. Because these areas are above floor level, it is important to protect these associates from ...

How To Safely Access Pallets When Loading And Removing From ...

As more operations add pick modules, rack supported platforms, and elevated work platforms to increase the throughput and capacity of their picking zones, facility owners need to be aware of safety requirements for fall prevention measures that protect workers. These ...

Keep Workers At Floor Level Safe From Falling Objects With ...

Installed on elevated work platforms, pick module walkways, and rack supported platforms, kickplates (also called toe boards or toe guards) protect associates working at floor level from objects that may slide or fall off the structure overhead. These vertical plates ...

How Elevated Work Platform Guardrails Enhance Worker Safety

With warehouse and distribution center storage at a premium, many operations are looking up and maximizing the overhead space in their facilities to expand their picking and fulfillment capacity. By utilizing elevated work platforms, pick modules, or rack supported platforms, ...