Why Pallet Flow Systems Are Designed For Specific Pallets And ...

The vast majority of industrial steel storage rack systems—including pallet flow (or “gravity flow”) rack—are engineered specifically for a single storage purpose. Likewise, when designing a high-density pallet flow system, there are a number of variables that must be taken ...

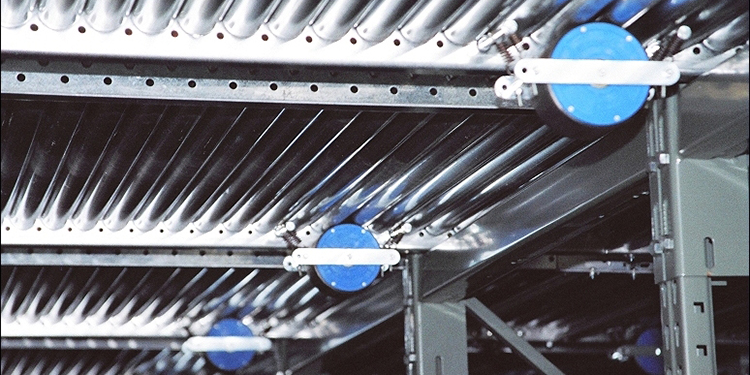

Applying Pallet Separators, Speed Controllers To Flow Rack

Because high-density pallet flow (also called “gravity flow”) rack is engineered to hold multiple pallet loads in a lane with a downward pitch, they are increasingly popular for use in case-picking operations. Full pallets are loaded from the back, or ...

Best Practices In Safe Operation Of Pallet Flow Rack

Pallet flow rack (also sometimes called “gravity flow”) is a high-density, dynamic storage system engineered to hold up to 20 pallets in a single lane. Loaded back to front for first-in/first-out load access, the pallets ride atop gravity wheel or ...

Comprehensive Resources For Safe Rack Design, Use Detailed In RMI’s ...

The safe use of a storage rack system is key to the ongoing productivity of a warehousing operation. That’s why members of RMI will both share insights from the current standards for the design, testing and utilization of industrial steel ...

Rack System Enhancements That Further Mitigate Forklift Impacts

A previous blog entry reviewed a selection of optional guarding accessories. These add-ons are applied at the time of installation—or as a later retrofit—to aisle-side or end-facing rack columns (or to the floor in front of them) to minimize the ...

RMI Seminar At ProMat To Address Rack Safety In The ...

With the holiday shopping season officially starting a week ago on Black Friday (or—in some cases—a week or two prior, as retailers offered special discounts ahead of Thanksgiving to get a jump on the competition for consumers’ dollars), the popularity ...

Hour-Long RMI Webinar Overviews Rack Safety 101

Several members of RMI recently hosted an online learning session to educate participants on the fundamentals of rack assembly, installation, operator training, inspections and maintenance. The “Rack Safety 101” webinar—available for free—highlights the best practices in industrial steel storage rack ...

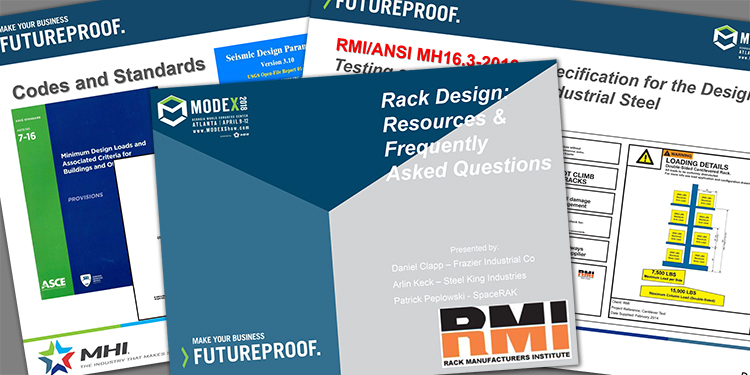

Have Questions About Rack Design? Watch This RMI Educational Session

In a two-part presentation delivered by RMI during MODEX 2018, members shared insights about the current standards for the design, testing and utilization of industrial steel storage racks and answered multiple, common questions on the topic. Entitled “Rack Design: Resources ...

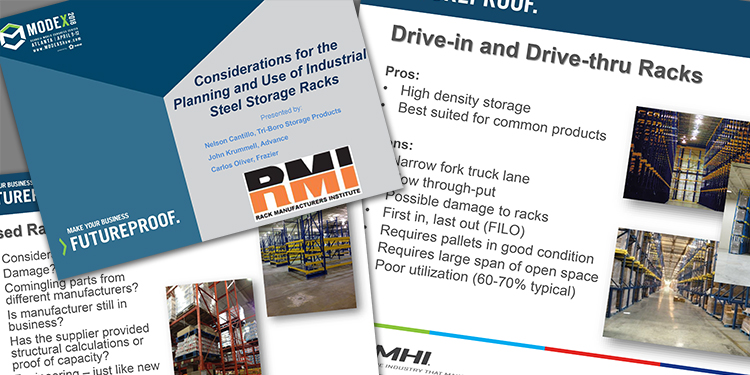

Newest Racking Technologies And How To Pick The Safest Solution ...

During MODEX 2018, held this past April in Atlanta, members of RMI presented a free, on-floor seminar to attendees. Entitled “Considerations for the Planning and Use of Industrial Steel Storage Racks,” the 40-minute session’s slides and audio were recorded for ...

Learn More About Rack Installation And Safety Inspections In RMI’s ...

The responsibility for safe industrial steel storage rack ownership and usage does not end at installation. Instead, it’s an ongoing process that includes several elements—including regular, routine inspections—to ensure a safe workplace. To help both potential and current end users ...