How Picker Ergonomics Is Improved By Utilizing Pallet Separators In ...

Engineered to hold multiple pallet loads in individual lanes pitched downward, high-density pallet flow (or “gravity flow”) rack is frequently used in case-picking operations. In these systems, full pallets of product are loaded from the back (or “charging”) end and ...

Safeguard Rack Columns Against Forklift Impacts With These Five Protective ...

To help protect rack columns from forklift and other vehicle impacts, there are a number of optional rack guard accessories that can be added to aisle-side or end-facing rack columns (or to the floor in front of them). Additionally, for ...

The “Dos And Don’ts” Of Pushback Rack

Engineered to store pallet loads on both sides of an aisle, industrial pushback racking storage systems deliver cubic densities that are approximately 25% to 65% greater than selective racking. The systems are built with a series of nested carts that ...

Jammed Pallet Flow System? Follow These Best Practices To Safely ...

Pallet hang-ups can happen in even the best maintained, properly loaded pallet flow rack system (also known as “gravity flow”). Jams can be caused by a variety of reasons, including a pallet that’s settled onto the tracks, debris in the ...

How Pallets Contribute To The Safe Use Of Pushback Rack ...

As with the vast majority of industrial steel storage rack systems, last-in/first-out (LIFO) pushback racking systems are designed for use with specific pallet types, loads and rack configurations. Operators, therefore, should be trained to only load a pushback system with ...

The “Dos and Don’ts” Of Pallet Flow Rack

Whether you own a pallet flow rack system (also referred to as “gravity flow” rack), or are considering investing in one, ownership comes with a variety of responsibilities. These include ensuring that the structure complies with applicable standards and is ...

Don’t Miss RMI’s Two ProMatDX 2021 Education Seminars On Rack ...

At ProMatDX 2021, members of the Rack Manufacturers Institute (RMI) will present two separate education sessions covering the safe design and use of industrial steel storage rack. Open to all ProMatDX attendees free of charge, the two sessions will include ...

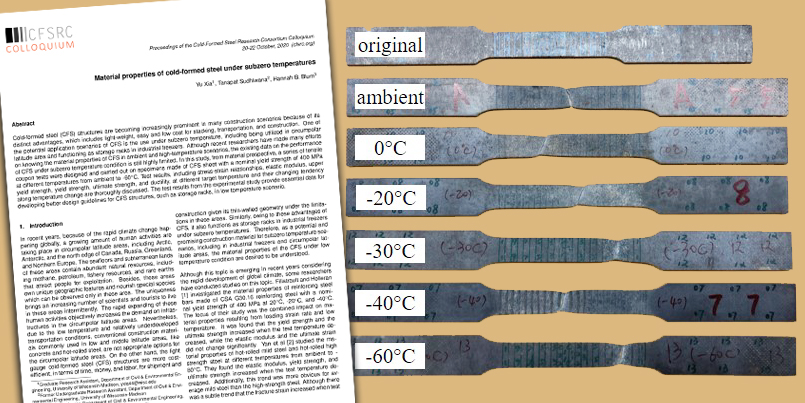

New White Paper Shares Findings From Testing Cold-Formed Steel In ...

Cold-formed steel (CFS) is used in the construction of both building structures and storage racks. It is also finding application in colder environments. These include key components of industrial steel storage racks used in cold-storage freezers and buildings in colder ...

RMI Requests Volunteers To Approve Updated Storage Rack Standard

The Rack Manufacturers Institute (RMI) is proposing revisions to the American National Standard for industrial storage racks, ANSI MH16.1-2012(R2019), and requests volunteers to serve on an approval committee to review and approve the revised standard. Individuals interested in participating on ...