Planning Your Rack System

With the right combination of equipment, you can meet your varied customers’ needs. The complexity of warehousing operations has been on a steady increase for the past decade or so. Now add in the pandemic and explosive demand for ecommerce, ...

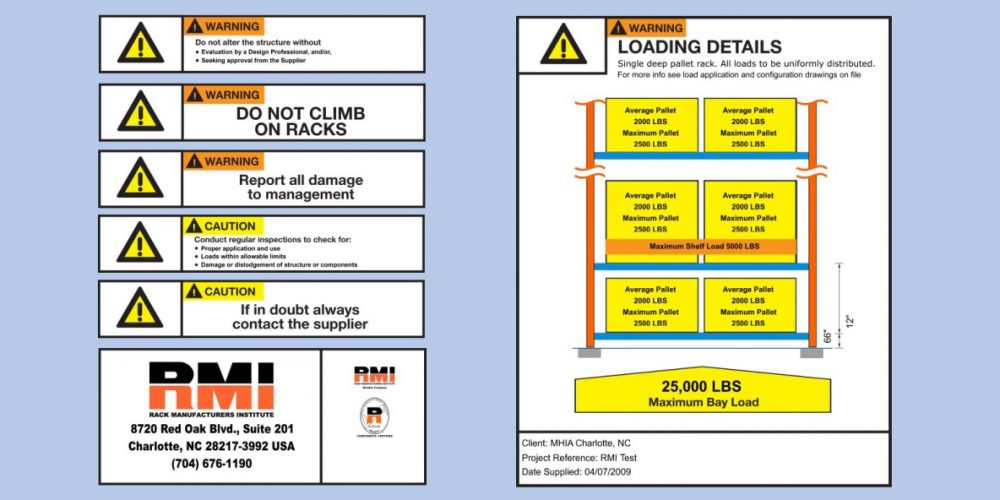

Load Plaques: Why Your Rack Installation Needs Them

When industrial steel storage rack installations have stamped and sealed engineering documents or load application and rack configuration (LARC) drawings, they should be kept on-site within the facility. These documents include critical details about the maximum safe capacity of the ...

Using Storage Rack Outside? Follow These Design And Use Best ...

Not every industrial steel storage rack installation is inside the four walls of a warehouse, distribution center or big box store. Instead, some racks are erected outside a building to store goods outside, frequently because of convenience or necessity. Like ...

RMI Requests Volunteers To Approve Updated Storage Rack Standard

The Rack Manufacturers Institute (RMI) is proposing revisions to the American National Standard for industrial storage racks, ANSI MH16.1-2012(R2019), and requests volunteers to serve on an approval committee to review and approve the revised standard. Individuals interested in participating on ...

Rack Safety, Design Pivotal In Growth Of MHI’s Oldest Industry ...

This article by Stephen Murdock originally appeared in the fourth quarter 2020 issue of MHI Solutions magazine and has been reprinted in its entirety with permission. The Rack Manufacturers Institute (RMI), officially the oldest Industry Group in MHI, has seen ...

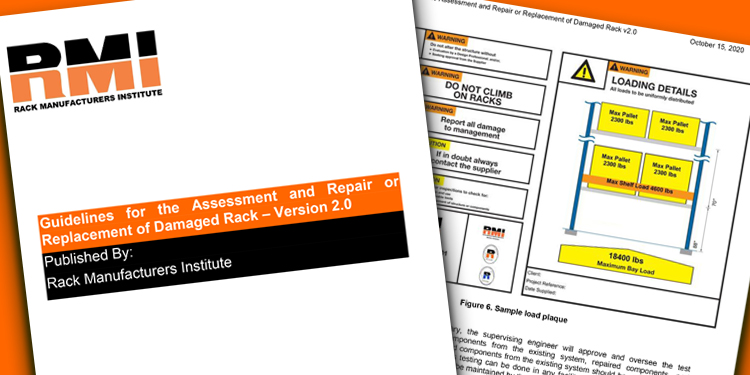

Updated Rack Repair Guidelines Released by RMI

The Rack Manufacturers Institute (RMI) has updated its existing publication, Guidelines for the Assessment and Repair or Replacement of Damaged Rack, with the latest information as a reference for owners and users of industrial pallet rack systems. The latest release, ...

Key Considerations For The Design And Use Of Dual-Bay Drive-In, ...

Designed and engineered for highly dense, two-at-a-time loading, unloading, and storage of pallets of uniform product, dual-bay drive-in and drive-thru storage racking maximizes the available cube of warehouse or distribution center. Because these systems minimize the number of aisles needed ...

Best Practices For Double-Wide Bay Drive-In, Drive-Thru Pallet Rack Safety

Delivering high-density storage, dual-bay drive-in and drive-thru storage racking is used to hold multiple pallets of the same product type. These systems — engineered with double-width bay openings that enable two pallets to be loaded simultaneously — create even more ...

Use Rack Load Capacity Plaques And LARC Drawings For A ...

To ensure a safer, and, therefore, more productive operation, owners of industrial steel storage racking are responsible for posting rack load capacity plaques in conspicuous locations, and should refer to the system manufacturer’s load application and rack configuration (LARC) drawings ...

Key Considerations For Drive-In Rack Design, Use

Ideal for maximizing the available cube within a facility, drive-in rack is designed and engineered for highly dense storage of multiple pallets of uniform product. Because it eliminates multiple travel paths and access aisles, drive-in rack can create additional pallet ...