Rack Codes & StandardsRack Design & InstallationRack Inspection & MaintenanceRack Repair & ReconfigurationUncategorized

A Look at ANSI MH32.1

In order to safeguard your employees on elevated work surfaces, you’ll need to follow these standards. In the warehouse, much of your employee’s work will take place in overhead work areas that are designed to maximize the vertical space you ...

How Rotationally Rigid Connections Enhance Rack Stability In Seismic Events

Depending on where a warehouse or distribution center (DC) is located within the United States, the design and engineering of its industrial steel storage rack structures may be subject to seismic requirements. As outlined in RMI’s ANSI MH16.1: Specification for ...

Use These Specifications To Ensure The Safest Stairway Design For ...

To access overhead work areas for picking—such as rack supported platforms, elevated work platforms, and pick modules—workers must climb one or more flights of stairs. Because these areas are above floor level, it is important to protect these associates from ...

How To Safely Access Pallets When Loading And Removing From ...

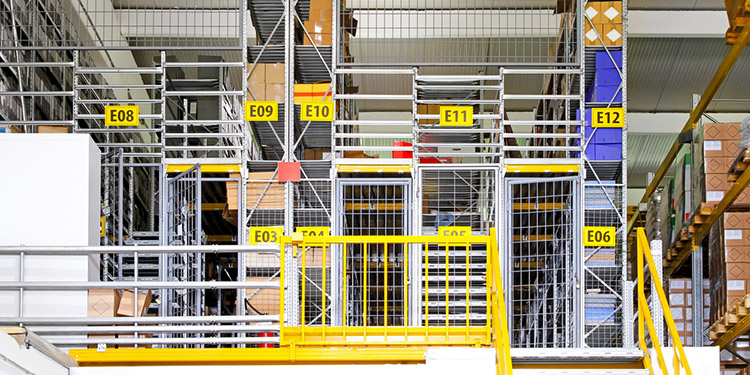

As more operations add pick modules, rack supported platforms, and elevated work platforms to increase the throughput and capacity of their picking zones, facility owners need to be aware of safety requirements for fall prevention measures that protect workers. These ...

Keep Workers At Floor Level Safe From Falling Objects With ...

Installed on elevated work platforms, pick module walkways, and rack supported platforms, kickplates (also called toe boards or toe guards) protect associates working at floor level from objects that may slide or fall off the structure overhead. These vertical plates ...

How Elevated Work Platform Guardrails Enhance Worker Safety

With warehouse and distribution center storage at a premium, many operations are looking up and maximizing the overhead space in their facilities to expand their picking and fulfillment capacity. By utilizing elevated work platforms, pick modules, or rack supported platforms, ...

The Importance Of Horizontal Clearance In Seismic Storage Rack Installations

Everything moves when an earthquake occurs. That includes the ground, the walls and support columns within a warehouse or distribution center, and the storage rack systems installed inside those structures. To minimize the risk of injury to any persons working ...

How Brace Panels Support Cantilevered Storage Rack Columns

Each cantilevered storage rack system is designed and engineered to match the requirements of the loads that will be placed and stored in it. Consisting of vertical columns from which horizontal arms project perpendicularly on one or both sides — ...

Understanding End Caps: Why They Might Be Used On Cantilevered ...

Whether they’re constructed from roll-formed steel or structural steel, cantilevered storage rack incorporates central, vertical columns from which horizontal arms project perpendicularly on one or both sides. Because the ends of the arms and bases are exposed, an optional steel ...