How Seismic Design Categories And Site Coefficients Impact Safe Rack ...

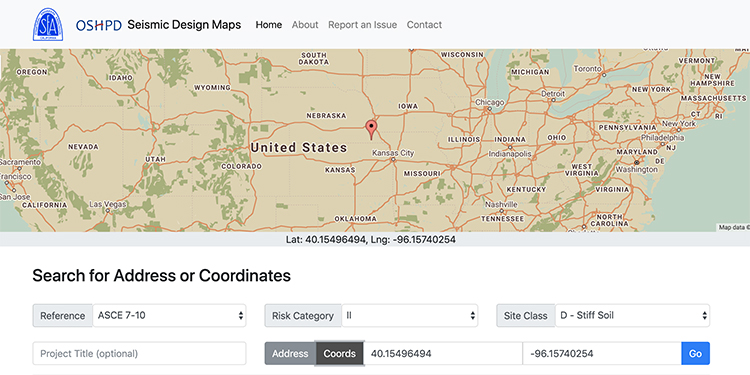

Design decisions for racks to be used in facilities with a greater risk of seismic activity are based on a number of factors, including seismic design categories and site coefficients. Information about each is used by a qualified rack engineer ...

Load Handling And Elevated Work Platforms: How To Ensure Safe ...

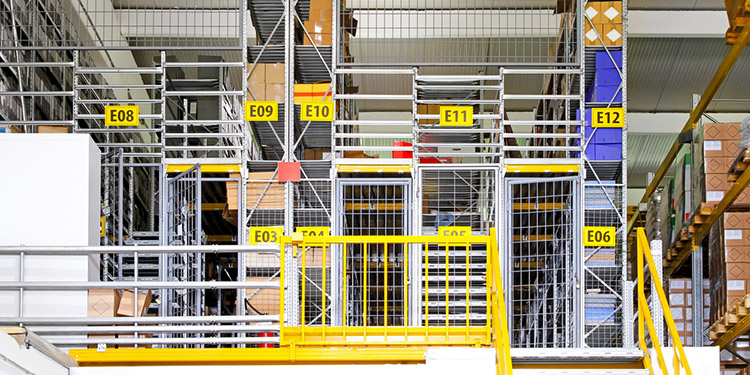

To replenish pallets of product picked by associates working in pick modules or on rack supported platforms, most facilities use forklifts to deliver the loads to a pallet drop zone at an aisle-side ledge. While guardrails are required by the ...

The Basics Of Safe Guardrails For Elevated Work Platforms

To maximize the overhead space in their facilities, many operations utilize elevated work platforms, pick modules, or rack supported platforms upon which workers access stored items. Because they’re working above ground level, it’s important to integrate permanent fall protection—specifically guardrails—around ...

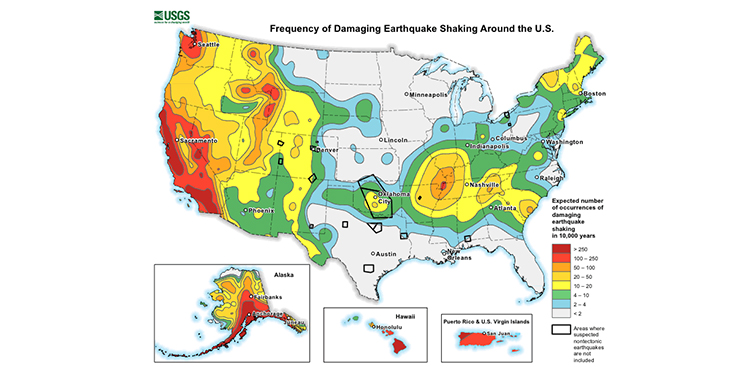

Will Your Rack Design Require A Seismic Force Review?

It’s a common misconception that seismically designed rack is only found west of the continental divide. In fact, earthquake activity has been documented in multiple regions throughout the U.S., including the Midwest and Southeast. That’s why, depending on where within ...

Safety Specifications For Pick Module Stair Design

Associates working within pick modules or on rack supported platforms to retrieve items stored above the facility floor access those higher levels via stairways. Protecting those workers from falls is, therefore, of critical importance. For that reason, the safe design ...

Eight Ways Welded Wire Decking Enhances Storage Rack Safety

Fabricated of welded wire mesh with an integrated support structure of reinforcing channels or support wires, welded wire rack decking enhances the safety of personnel working in industrial steel storage rack aisles (when properly engineered, installed and used in accordance ...

Before Relocating Or Reconfiguring Rack Watch RMI’s New Safety Video

To keep up with changing customer expectations and handling needs, facilities are changing faster than ever before. Because of its inherent flexibility, operations might be taking a closer look at their current industrial steel storage rack installation and considering either ...

Rack Repair Kits: What You Need To Know

When a damaged rack section is assessed by a qualified, professional rack engineer, it may be determined that a repair can be completed with a rack repair kit as opposed to field welding. That’s because, as outlined in Appendix 1 ...

Nine Things To Look At During A Rack System Inspection

Committing to regular, routine inspections of industrial steel storage racking is a key measure toward ensuring the safety and performance of a rack structure. To help rack owners and facility operators perform such inspections, RMI’s recent ProMat 2019 presentation, “Storage ...