How Point Loads And Uniformly Distributed Loads Affect Safe Rack ...

When placed in industrial steel storage racks, a uniformly distributed load is one whose weight is evenly spread over the entire surface of the rack’s beams or deck. Conversely, a point load is one with its weight significantly concentrated in ...

Wire Rack Decking Safety 101

Placed on pallet rack beams, rack decking spans the distance between them. The decking, fabricated from welded wire mesh with a support structure of reinforcing channels (or support wires), provides added support to items stored on a pallet. It also ...

Rack Beam Deflection Limits Specify The Maximum Permissible Amount Of ...

When a pallet load is placed on the load support beams in industrial steel storage rack, the beams will naturally deflect, or bow, under the load. Because of this, when a qualified rack design engineer determines the requirements for a ...

Beware Of Leaning Or Bowed Pallet Rack Columns

While some column distortion may be acceptable in a loaded industrial steel pallet rack structure, if a column is leaning (out-of-plumb) or bowed (out-of-straight) beyond a certain point, its capacity will be significantly reduced. Those conditions are unsafe and increase ...

Best Practices In The Safe Design And Use Of Cantilevered ...

To ensure the safe design, manufacture and installation of cantilevered rack systems, RMI publishes the ANSI MH16.3 Specification for the Design, Testing and Utilization of Industrial Steel Cantilevered Storage Racks. Designed and engineered to store very long loads — such ...

Building Codes And Their Importance To Rack Design

In spite of being a standalone structure, the safety of an industrial steel storage rack’s design and installation is nearly always vetted by one or more local jurisdictions — including state, county, or local municipality. The reason? The International Code ...

Thinking About Buying Used Rack? Consider These Factors Before Signing ...

There’s an extensive market for used pallet storage rack, typically made available because its former warehouse home has been shuttered or the system has been replaced. Although it’s true that used storage rack is often priced at a discount over ...

Key Considerations For The Design And Use Of Dual-Bay Drive-In, ...

Designed and engineered for highly dense, two-at-a-time loading, unloading, and storage of pallets of uniform product, dual-bay drive-in and drive-thru storage racking maximizes the available cube of warehouse or distribution center. Because these systems minimize the number of aisles needed ...

Best Practices For Double-Wide Bay Drive-In, Drive-Thru Pallet Rack Safety

Delivering high-density storage, dual-bay drive-in and drive-thru storage racking is used to hold multiple pallets of the same product type. These systems — engineered with double-width bay openings that enable two pallets to be loaded simultaneously — create even more ...

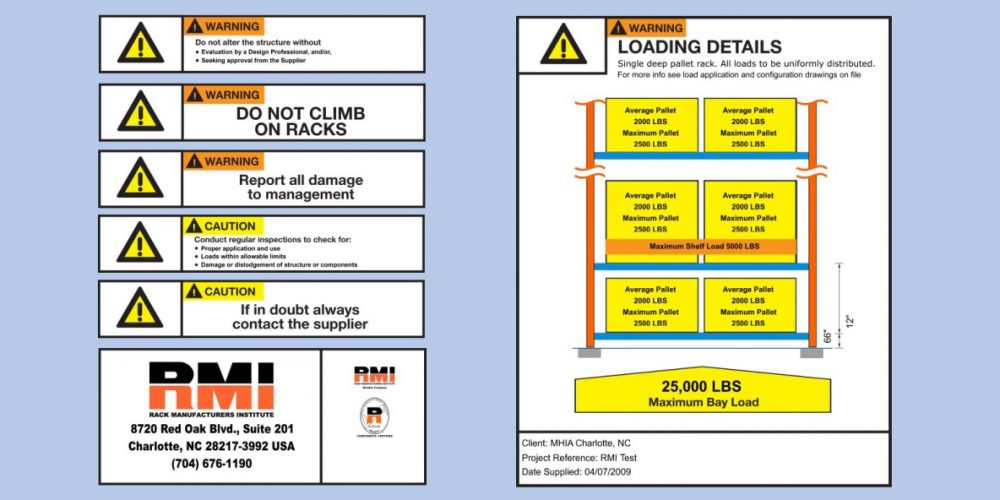

Use Rack Load Capacity Plaques And LARC Drawings For A ...

To ensure a safer, and, therefore, more productive operation, owners of industrial steel storage racking are responsible for posting rack load capacity plaques in conspicuous locations, and should refer to the system manufacturer’s load application and rack configuration (LARC) drawings ...